On-Site Chlorine Generator

Create Your Own Chlorine

The use of packaged chlorine for disinfecting commercial pools—whether liquid, solid, or gaseous—now comes with many disadvantages:

- Hazardous Nature of the Products

- Deterioration of Chlorine Quality Over Time

- High Operating and Transportation Costs

- Regular Maintenance of Installations

- Significant Environmental Impact

IPOQLOR® allows you to produce chlorine on-site from salt and softened water, in a cost-effective and fully autonomous way:

3 kg of salt are enough to produce 1 kg of active chlorine. 9 kg of salt can produce the equivalent of a chlorine container.

With 10 years of experience since the installation of the first unit in 2011, iPOQLOR® (formerly Pure Chlore) benefits from our full French expertise. It is the only on-site chlorine generator that is entirely designed and manufactured in France.

iPOQLOR® is suitable for all types of commercial pools:

Aquatic centers, municipal pools, hotels, campsites, condominiums, etc...

The effectiveness of chlorine without the drawbacks

Quality

- On-site production of fresh chlorine with a consistent concentration, without degradation

- Less clogging of injection points due to the low mineral content of the produced solution

- Reduced Chloramine Levels

Savings

- Low Salt Cost

- Reduced Labor Requirements

- Lower pH Adjustment Needs

- One Production Unit, Multiple Pools Treated

Safety

- Elimination of Product Transport and Storage dangereux

- No More Handling of Chemicals

- No Chlorine Vapor Emissions

- H2 Detector Included as Standard

- Remote Monitoring (GSM, Internet)

Simplicity

- Plug & Play Commissioning

- Low Maintenance

- Integration with Existing Installations

Keep an Eye on Your Chlorine Production

Physical Ethernet RJ45 connection for accessing all operational data via the Connect Pro platform.

- Production Time

- Sodium Hypochlorite Solution Temperature

- Events, Alarms

- Graphs, Production Curves (Daily, Weekly, Monthly…)

Real-Time View of Your Device's Various Parameters

Data and Alarm History

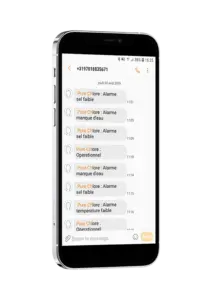

GSM Connection: A dedicated SIM slot is provided in the control unit.

The user can assign up to three phone numbers to receive SMS notifications for any alarm detected by the system.

How it Works

The system is continuously supplied with mains water connected to a softener (single or dual, depending on the model).

The softened water supplies both the brine tank and the production circuit.

Brine Tank: The salt used must comply with one of the following three standards: NF EN 973 Quality A, NF EN 14805 Type 1, or NF EN 16401 Quality A.

The brine is mixed with softened water at the inlet of the production circuit, with a salt concentration of approximately 26 g/L.

The resulting mixture is injected into the production cell circuit at a very low flow rate, depending on the model, ranging from 17 to 70 L/h. Sodium hypochlorite is thus produced continuously.

The hydrogen gas, which is lighter than air and generated during production, is vented outside the facility with the help of a blower for models producing more than 250 g/h. To enhance safety, a hydrogen detector is installed in the technical room.

The produced sodium hypochlorite is directly discharged into the production tank, ready for pool treatment. Average concentration: 0.8 g/L of active chlorine.